Control of Potential Mutagenic Impurities: PMIs

2017.09.13

Recently, health authorities pay attention to residual impurities in drug substances and drug products, and require pharmaceutical companies to control them strictly. Especially, the inquiries on PMIs control strategy for clinical trial/ new drug application in Europe and US have been often observed. According to the ICH guideline M7, the acceptance criteria for PMIs in commercial phase may be 1.5 µg/day as a case, and this value is considerably strict compared to general impurities. Therefore in addition to development of highly-sensitive analytical methods (e.g. ppm level), change of API manufacturing process and formulation design may be considered necessary as a potential scenario which would influence a development program timeline.

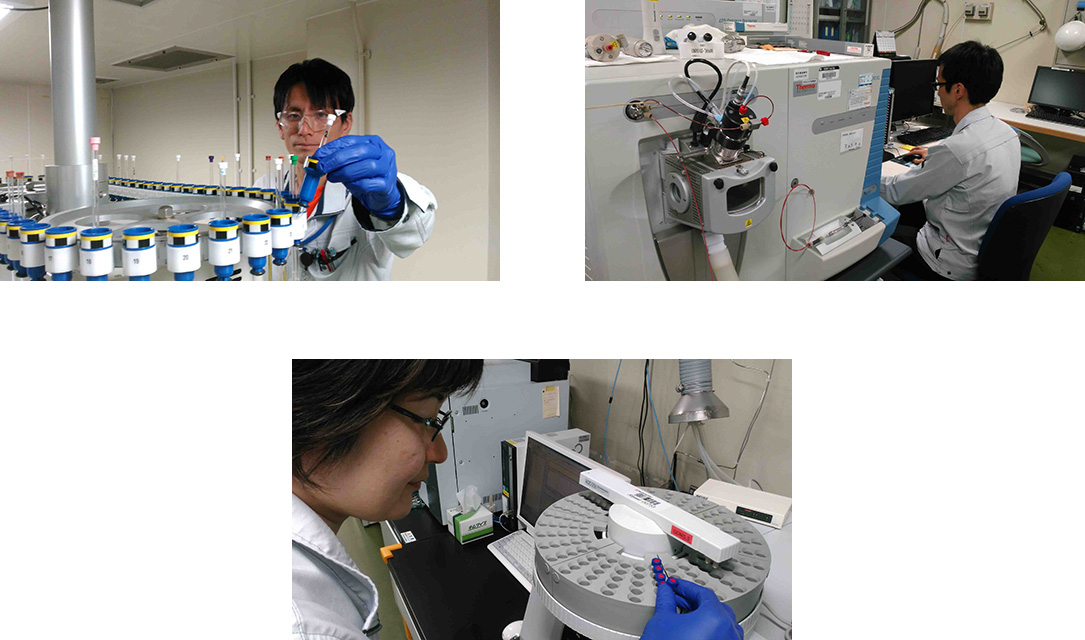

For control of PMIs, SPERA PHARMA investigates the potential and actual impurities to avoid the residual risk in raw materials, reagents and isolated intermediates in manufacturing process, as well as possible reaction intermediates (non-isolated intermediates) and each impurities in these raw materials/ intermediates. To assure adequate quality of API, process chemists and analytical chemists design the impurity control strategies and provide highly-sensitive analytical technologies, considering each characteristic of PMIs.

SPERA PHARMA has developed more than 300 highly sensitive analytical methods to control the residual level of PMIs less than 10 ppm, therefore we are able to respond to the increasingly strict requirement of health authorities.

While difficulties in new drug R&D are increasing, we brush up the cultivated technologies to meet demands of our customers who are committed to development of new drugs, and to contribute certainly to solving PMIs control challenges.

page top